Vijayawada Thermal Power Station Construction

Product Details:

X

Product Description

Due to the high value of our Vijayawada Thermal Power Station Construction service, we have emerged as an admirable service provider from Andhra Pradesh, India. This service is executed under the stern observation of our experts having immense knowledge in this field. When we venture into these construction projects, we assure that complete perfection is rendered in our thermal power station construction projects. This Vijayawada Thermal Power Station Construction service is provided on the basis of information detailed by our clients. Our offered service is highly admired for its cost-effectiveness, reliability, timely completion and successful project execution.Features of Vijayawada Thermal Power Station Construction:

1) High quality construction materials are used for making the structure robust.2) Our team of experts are highly knowledgeable in this domain.

3) Special attention for making drainage and filling arrangements.

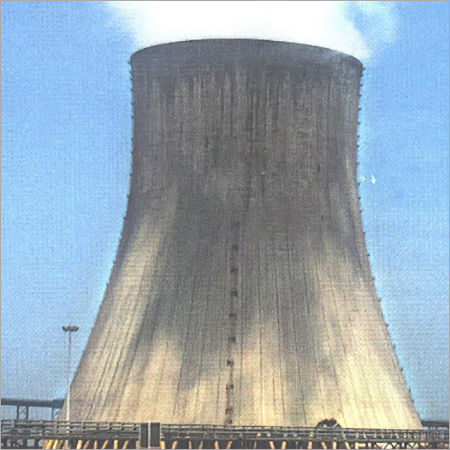

VTPS 1x500 MW (Vijayawada Thermal Power Station, lbrahimpatnam):

1) Chimney pile breaking for foundation2) Chimney earth work and RCC Raft

3) Natural draught cooling tower

4) TG Raft Foundation RCC

5) TG Deck Concrete

6) 'O' level foundations for STG ond ESP

7) Stilling chamber PARSHAL FLUME-Distribution chamber and recycling water pump house

8) Miscellaneous works for other works

9) Connecting channel and fore boy for pump house

Construction Technology:

The entire process of construction goes under the directions of our team of well-trained professionals, they modularize the parts to be installed ensuring safety & quality, improving work efficiency and the objectives of shortening the construction period. Further, as per the requirement of our customers, we have developed large tools and other equipments for transporting modules to their installation locations.Preventive Maintenance:

In order to ensure the quality, safety and maintain performance, large equipment is periodically replaced after operation at power stations. For this service, a special technology is required to replace the equipment because it is a large process.State-of-the-Art Thermal Power Generation

Vijayawada Thermal Power Station employs advanced pulverized coal-fired boilers and water-cooled condensers, ensuring consistent and high efficiency in electricity generation. Its strategic location in Andhra Pradesh makes it a critical contributor to the states energy infrastructure, reliably supplying power to industries, businesses, and households.

Robust Environmental Protection Features

The station is equipped with modern environmental control technologies including electrostatic precipitators and flue gas desulphurization units. These systems significantly reduce particulate emissions and sulfur dioxide, minimizing the environmental footprint and helping maintain air quality within regulatory standards.

Long-Term Reliability and Capacity

With a total installed capacity of 2,260 MW and a projected operational life exceeding 30 years, the plant assures energy stability and longevity for the region. Its 1,000+ acre site facilitates future expansions and continuous improvements in technology and environmental safeguards.

FAQs of Vijayawada Thermal Power Station Construction:

Q: How is electricity generated at Vijayawada Thermal Power Station?

A: Electricity is produced using pulverized coal-fired boilers that heat water, creating steam to drive turbines connected to generators. The water-cooled condenser system then cools the steam, making the process efficient.Q: What is the installed capacity of each unit at the station?

A: Vijayawada Thermal Power Station has six units: Units 1-3 each have an installed capacity of 210 MW, while Units 4-6 each have 500 MW, amounting to a total capacity of 2,260 MW.Q: Where is the Vijayawada Thermal Power Station located?

A: The station is situated in Vijayawada, Andhra Pradesh, India, strategically placed to serve the states and regions electricity needs.Q: What environmental controls are used in the plant?

A: Environmental controls include electrostatic precipitators to capture particulate matter and flue gas desulphurization to reduce sulfur dioxide emissions, helping to maintain local air quality.Q: What is the expected operational life of the power station?

A: The plant is designed for a life span of 30 years or more, ensuring sustained power generation for decades.Q: How is the generated electricity connected to the power grid?

A: Electricity from the station is transmitted via 220 kV and 400 kV grid connection voltages, integrating smoothly into regional power networks and ensuring reliable distribution.Q: What are the benefits of this thermal power station to the region?

A: The station provides a stable electricity supply, supports economic growth, creates regional employment, and incorporates environmental technologies to mitigate pollution.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Completed Project' category

Offering Quality Services For Road Construction, Bridge And Power Plant Construction With Outstanding Features For A Longer Span Of Time....

HAYAGREV CIVIL ENGINEERING PVT. LTD.

GST : 37AACCH0266J1ZL

GST : 37AACCH0266J1ZL

20/584-1, Namaste Board Lane, Cuddapah - 516001, Andhra Pradesh, India

Phone :08071931642

|

|

HAYAGREV CIVIL ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |