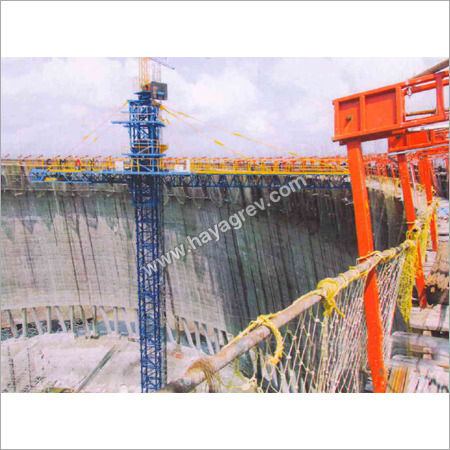

NDCT Shell Under Construction

Product Details:

X

Product Description

Fostered with years of market understanding, we Hayagrev CivilL Engineering PVT LTD, located in Andhra Pradesh, India, are affianced in rendering NDCT Shell Under Construction. Our expertise is in constructing cooling towers as per information laid down by our clients. We are equipped with contemporary machinery and technologies that help us to construct the towers that can withstand in any weather. Besides, the construction work undertaken by us is executed within the stipulated time frame in hassle free manner. Our clients can take benefit of this NDCT Shell Under Construction at very economical prices.Features:

1) On-time construction of structure as per layout finalized by client.2) Backed by technically advanced construction machinery for rendering construction services in a hassle-free manner.

3) Ability to make almost all kind of shell design.

4) Assures zero material wastage during construction.

5) Renowned for accomplishing construction work within committed time frame.

6) Dimensional stability of constructed shells.

7) Use of topnotch quality construction materials that are sourced from the reliable suppliers of market.

Advanced Hyperboloid Design

The shells hyperboloid shape is chosen for its superior structural stability and efficient thermal exchange, essential for cooling tower applications. This geometry ensures even load distribution, minimizes material usage, and improves the towers endurance against wind stress, making it an optimal choice for both power plants and industrial settings.

Engineered for Indian Conditions

Each cooling tower shell is engineered to meet local wind loads and environmental requirements, ensuring resilience and performance in diverse geographical locations across India. Regular structural checks are integrated throughout and after construction, safeguarding reliability and operational safety for decades to come.

FAQs of NDCT Shell Under Construction:

Q: How is the hyperboloid shape beneficial for natural draft cooling towers?

A: The hyperboloid shape enhances structural stability and improves thermal efficiency by facilitating optimal airflow and load distribution. This design also reduces the amount of construction material required, helping maintain cost-effectiveness and reliability in cooling tower operations.Q: What construction materials are used for the NDCT Shell?

A: The shell is constructed using high-strength steel bars for reinforcement and M40 grade concrete, or as specified, ensuring durability, wind resistance, and optimized thermal performance during operation.Q: When are structural integrity inspections performed?

A: Regular structural integrity checks are conducted throughout the construction phase and continued after completion, following industry standards and project-specific schedules to guarantee safe and reliable operation.Q: Where can these cooling tower shells be implemented?

A: NDCT shells are suitable for installation in power plants and industrial facilities throughout India, with customization options to meet the demands of different locations and applications.Q: What is the typical process for constructing the NDCT Shell?

A: The construction process involves site preparation, precise placement of high-strength steel bars, casting of M40 grade concrete using shuttered forms, and ongoing quality inspections to ensure the shell meets all design specifications and safety standards.Q: How does the shells surface finish impact its performance?

A: A shuttered concrete finish not only provides durability and resistance to environmental wear but also ensures a smooth exterior, which aids in minimizing thermal losses and maintaining long-term cooling efficiency.Q: What are the long-term benefits of using this cooling tower shell?

A: With its robust materials, optimized design, and regular maintenance protocols, the NDCT shell is expected to provide reliable service for over 30 years, supporting efficient cooling operations and reducing overall lifecycle costs for power and industrial facilities.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Completed Project' category

Offering Quality Services For Road Construction, Bridge And Power Plant Construction With Outstanding Features For A Longer Span Of Time....

HAYAGREV CIVIL ENGINEERING PVT. LTD.

GST : 37AACCH0266J1ZL

GST : 37AACCH0266J1ZL

20/584-1, Namaste Board Lane, Cuddapah - 516001, Andhra Pradesh, India

Phone :08071931642

|

|

HAYAGREV CIVIL ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |