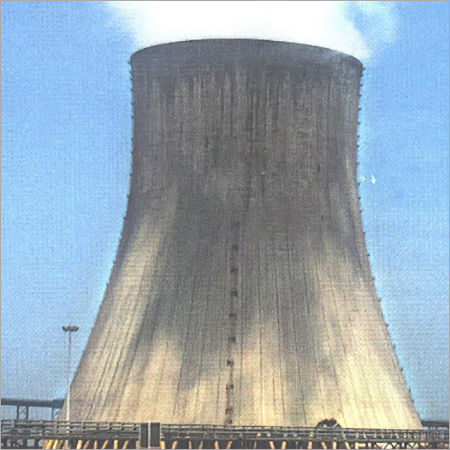

Mettur Thermal Power Station Construction

Product Details:

X

Product Description

With rich industry experience, we Hayagrev Civil Engineering PVT LTD, based at Andhra Pradesh, India, are providing our clients the best opportunity for Mettur Thermal Power Station Construction service. Our team of builders provides all the elucidations of construction right from conceptualization to project execution. As per client's budget, our offered construction service is rendered as per the detailed information. This service is rendered for constructing thermal power station in Mettur. Only contemporary technology and superior grade raw materials are used in the construction by our team of experts. This Mettur Thermal Power Station Construction is highly treasured owing to its timely work completion, reliability and flexibility.Features of Mettur Thermal Power Station Construction:

1) Use of contemporary machines and high quality construction materials.2) Service is completed within promised time frame.

3) Weather proof structures are constructed.

Advanced Ash Handling Systems

Mettur Thermal Power Station integrates both pneumatic and hydraulic ash handling technologies to efficiently manage waste by-products. These methods ensure safe transportation and disposal of ash, minimizing environmental impact and maintaining plant productivity. The dual-system approach provides flexibility and reliability in continuous plant operations.

Environmentally Compliant Operations

The station is designed to comply fully with CPCB norms, incorporating rigorous standards for pollution control. Continuous Emission Monitoring Systems (CEMS) are deployed to regularly track stack emissions, ensuring that all pollutants remain within permissible limits. This commitment guarantees cleaner operations and a healthier surrounding environment.

Strategic Water and Coal Management

Sourced from Stanley Reservoir, water is critical for plant cooling and operations. The facility processes approximately 3,000 MT of coal daily, ensuring consistent energy production. Spread over 1,300 acres, the plant layout is optimized for resource efficiency and operational safety.

FAQs of Mettur Thermal Power Station Construction:

Q: How is ash managed at Mettur Thermal Power Station?

A: Ash generated during coal combustion is handled by both pneumatic and hydraulic systems. Pneumatic methods use air pressure to transport ash, while hydraulic systems use water to move ash slurry to disposal areas, ensuring efficient and safe waste management.Q: What environmental standards does the plant adhere to?

A: The station complies with the Central Pollution Control Board (CPCB) norms, implementing strict measures to limit emissions and prevent environmental contamination through continuous monitoring and best operational practices.Q: When is stack emission monitoring conducted at the facility?

A: Stack emission monitoring is performed continuously using an advanced Continuous Emission Monitoring System (CEMS), providing real-time data on pollutants 24/7 and helping maintain environmental compliance.Q: Where is the water for the plant sourced from?

A: Water required for cooling and other operations is sourced directly from Stanley Reservoir, also known as Mettur Dam, providing a consistent and reliable supply for the thermal power station.Q: What is the process for coal consumption in daily operations?

A: Approximately 3,000 metric tons of coal are consumed each day, which is fed into boilers to generate steam for power production, ensuring uninterrupted electricity supply from the facility.Q: How does the 275-metre chimney benefit plant operations?

A: The tall chimney aids in effective dispersion of emissions, reducing ground-level pollutants and supporting compliance with environmental regulations, while minimizing the impact on local air quality.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Completed Project' category

Offering Quality Services For Road Construction, Bridge And Power Plant Construction With Outstanding Features For A Longer Span Of Time....

HAYAGREV CIVIL ENGINEERING PVT. LTD.

GST : 37AACCH0266J1ZL

GST : 37AACCH0266J1ZL

20/584-1, Namaste Board Lane, Cuddapah - 516001, Andhra Pradesh, India

Phone :08071931642

|

|

HAYAGREV CIVIL ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |