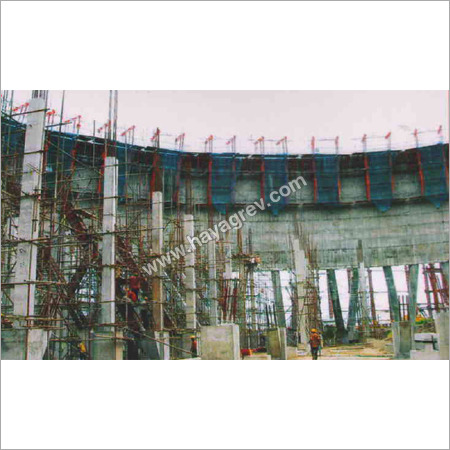

APEPDCL Thermal Power Project

Product Details:

X

Product Description

Operating from the prime location of Andhra Pradesh, India, we are a leading service provider indulged in undertaking APEPDCL Thermal Power Project. With the support of our builders, we undertake this project for the complete structure designing of the thermal power station. Also, our skilled engineers make use of superior quality construction materials in the construction of thermal stations to make it resistive against harsh weather. Additionally, we complete this APEPDCL Thermal Power Project within the stipulated time frame at reasonable prices.Key Points of APEPDCL Thermal Power Construction:

1) We plan to execute this project with an objective to shorten the construction period without compromising the quality and safety aspect.2) Before starting the construction of thermal power plant, our professionals visit the site and design the conceptual plan for the project.

3) We make use of superior quality concrete and other allied materials in the construction process of this plant.

Advanced Cooling and Emission Control

Our thermal power project uses water-cooled systems to efficiently regulate temperature and features dual emission controlselectrostatic precipitators and flue gas desulphurization. These technologies play a vital role in reducing pollutants and ensuring compliance with Indias environmental regulations set by MoEF and CEA.

Efficient Power Generation and Automation

Harnessing the capabilities of steam turbines in single or multiple stages, our plant maximizes electricity output while keeping auxiliary power consumption to 8% of gross generation. The adoption of SCADA or DCS control systems ensures seamless monitoring, automation, and superior operational reliability over its 30-year lifecycle.

FAQs of APEPDCL Thermal Power Project:

Q: How does the water-cooled system benefit the APEPDCL Thermal Power Project?

A: The water-cooled system efficiently absorbs and dissipates heat from the plants components, enhancing performance and aiding in maintaining optimal operating temperatures. This results in increased reliability and operational lifespan of critical equipment, as well as improved overall generation efficiency.Q: What emission control technologies are implemented at the project site?

A: The plant utilizes electrostatic precipitators, which remove particulate matter from flue gases, and flue gas desulphurization systems that reduce sulfur dioxide emissions. Combined, these technologies ensure the facility meets stringent pollution standards set by MoEF and CEA guidelines.Q: When does the operational life of the thermal power plant typically end?

A: The APEPDCL Thermal Power Project is engineered for a functional life span of approximately 30 years, depending on maintenance practices, upgrades, and prevailing operational conditions.Q: Where is the APEPDCL Thermal Power Project located, and who is the service provider?

A: This advanced thermal power plant is established in India, and APEPDCL serves as the service provider, offering reliable energy solutions and overseeing efficient plant management.Q: What is the process for controlling operations at the plant?

A: Operations are managed using sophisticated SCADA or DCS control systems, which allow real-time monitoring, automatic adjustments, and precise control over plant functions. This technology supports consistent performance, safety, and data-driven decision-making.Q: How much auxiliary power does the plant consume in relation to gross generation?

A: Approximately 8% of the plants gross electrical generation is allocated for auxiliary systems, ensuring smooth operation of critical infrastructure such as pumps, fans, control units, and emission controls.Q: What are the primary benefits of using both electrostatic precipitators and flue gas desulphurization?

A: Combining these emission control systems significantly reduces airborne pollutants, secures regulatory compliance, and promotes healthier air quality for the surrounding environment.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Completed Project' category

Offering Quality Services For Road Construction, Bridge And Power Plant Construction With Outstanding Features For A Longer Span Of Time....

HAYAGREV CIVIL ENGINEERING PVT. LTD.

GST : 37AACCH0266J1ZL

GST : 37AACCH0266J1ZL

20/584-1, Namaste Board Lane, Cuddapah - 516001, Andhra Pradesh, India

Phone :08071931642

|

|

HAYAGREV CIVIL ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |