275 Mts Height Chimney Construction

Product Details:

X

Product Description

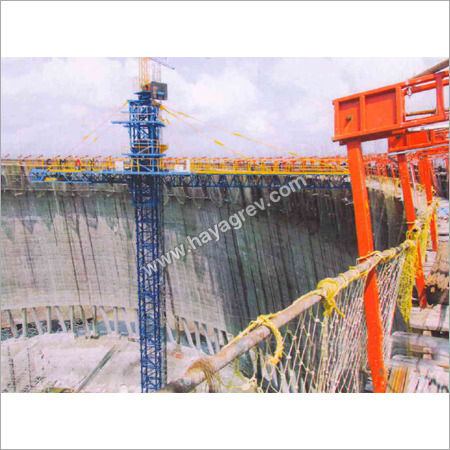

We Hayagrev CivilL Engineering PVT LTD, based at Andhra Pradesh, India, are considered to be one of the most commendable service providers of 275 Mts Hight Chimney Construction. This service for construction is rendered under the observation of our highly experienced team of professionals with the help of modern machinery in accordance with the set industry guidelines. Our offered service is rendered for construction of chimney with height of 275 mts. For successful execution of the rendered service, our team of builders pays utmost attention on the whole construction process. Highly admired for timely execution, hassle free management and reliability, our offered 275 Mts Hight Chimney Construction service is provided to the clients at highly competitive prices.Features of 275 Mts Height Chimney Construction:

1) Our constructed chimney is fully protected from adverse conditions.2) Highly strong, durable chimney is constructed.

3) Service is rendered within stipulated time frame.

Advanced Construction Techniques

Our slip forming and jump forming methods accelerate chimney erection while maintaining structural precision. These modern technologies allow for continuous pouring and minimal construction joints, reducing potential weak points and improving overall durability of the structure.

Comprehensive Inspection and Testing

We provide inspection manholes at multiple heights within the chimney, enabling regular examination and easy access for maintenance teams. Prior to commissioning, hydrostatic and smoke leakage tests are conducted, securing optimal operational safety for years to come.

Superior Safety Standards

ICAO-compliant aviation markings and high-temperature resistant materials guarantee that every chimney meets strict industry and international safety specifications, ensuring both operational reliability and airspace visibility.

FAQs of 275 Mts Height Chimney Construction:

Q: How is slip forming or jump forming technology implemented in 275-meter chimney construction?

A: Slip forming and jump forming technologies enable seamless vertical construction by continuously pouring concrete while moving the formwork upwards. This process reduces construction time and structural joints, resulting in a robust and uniform chimney structure.Q: What inspection facilities are integrated into the chimney for ongoing monitoring?

A: Inspection manholes are provided at various elevations within the chimney to facilitate regular inspection and easy access for maintenance, allowing for thorough assessment and early identification of any structural issues.Q: When are leakage tests conducted during the chimney construction process?

A: Hydrostatic and smoke leakage tests are performed after chimney completion and prior to commissioning. These tests verify airtightness and operational safety, ensuring the structure is ready for service.Q: Where are ICAO standard aviation markings applied on the chimney?

A: ICAO standard aviation markings are painted at strategic sections along the chimneys height to improve visibility for aircraft, adhering to international aviation safety regulations and enhancing airspace safety.Q: What is the maximum temperature resistance of the constructed chimneys flue liner?

A: The chimney is engineered to withstand flue gas temperatures up to 400C, ensuring reliable operation in high-temperature industrial environments such as thermal power plants, refineries, and cement factories.Q: How does the use of inspection manholes benefit the maintenance process?

A: Inspection manholes simplify routine maintenance and structural inspections by providing accessible entry points at multiple heights, helping identify potential concerns early and prolonging the operational lifespan of the chimney.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Completed Project' category

Offering Quality Services For Road Construction, Bridge And Power Plant Construction With Outstanding Features For A Longer Span Of Time....

HAYAGREV CIVIL ENGINEERING PVT. LTD.

GST : 37AACCH0266J1ZL

GST : 37AACCH0266J1ZL

20/584-1, Namaste Board Lane, Cuddapah - 516001, Andhra Pradesh, India

Phone :08071931642

|

|

HAYAGREV CIVIL ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |